How to made 20W fast car charger with a spiral cable ?

From Lirui Factory to Your Car ,specified production process for the fast car charger with spiral typeC cable

Creating a high-quality, safe, and efficient 20W fast car charger is a multi-step process that demands precision and expertise. Here's a detailed look at each stage of production:

1. SMT (Surface-Mount Technology): The Foundation of Performance

The heart of any electronic device is its Printed Circuit Board Assembly (PCBA). The journey begins with Surface-Mount Technology (SMT), a method for producing electronic circuits in which the components are mounted or placed directly onto the surface of printed circuit boards (PCBs). This automated process is crucial for creating the compact and complex circuitry required for a 20W fast charger.

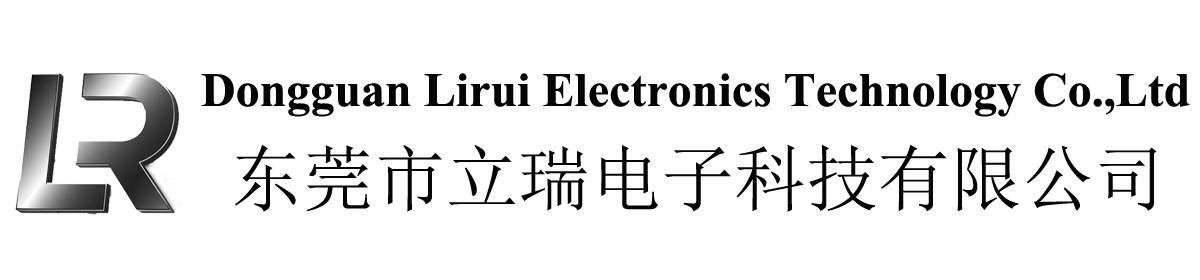

2. Plugin:Placing the Larger Components

After the automated SMT process places the smaller, surface-mounted components, the next step is the "Plugin" stage, also known as Through-Hole Technology (THT) insertion. Not all electronic components can be surface-mounted; larger and more robust parts like USB ports, large capacitors, and inductors often require manual or semi-automated insertion. During this critical step, skilled technicians or specialized machines "plug" the leads of these components through pre-drilled holes in the PCB, preparing them for soldering.

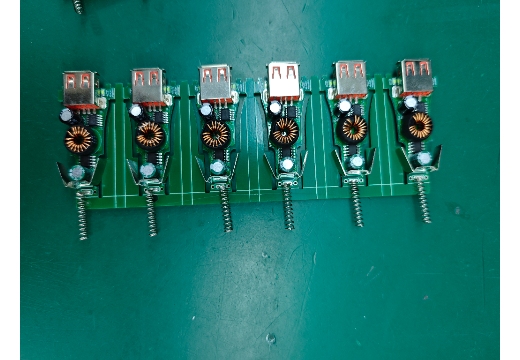

3.PCBA & Spiral Cable Soldering: Securing the Connections

Once all components—both surface-mounted and plug-in—are in place, they need to be permanently secured. This is achieved through a precise soldering process. For the newly inserted through-hole components, a technique called wave soldering is often used. The board passes over a "wave" of molten solder, which securely bonds the component leads to the PCB. This step ensures that all connections are strong, durable, and electrically sound. Then our workers will solder the spiral cables into the PCBA very carefully.

4. PCBA Testing: Ensuring Reliability

Quality control is paramount. Before the PCBA is moved to the assembly line, it undergoes rigorous testing. This can include:

Our workers guled the coiled cables again to make sure it's strong enough and durable when using ,then other workers will test the pcba at the first time .

5. Assembling the Charger: Bringing It All Together

With a fully tested and functional PCBA, the assembly process begins. This is where all the components of the car charger are brought together:

The PCBA is carefully placed into the charger's housing.

The USB-A connector and any other ports are integrated.

The outer casing is then securely fastened.

6. Function Testing (Twice!): The Ultimate Quality Check

To guarantee that every charger that leaves the factory is in perfect working order, it undergoes two rounds of comprehensive function testing. This involves plugging the charger into a power source and connecting it to a test device to verify:

Fast Charging Capability: Does it deliver the full 20W of power?

Power Delivery (PD) Protocol: Does it correctly communicate with the device to enable fast charging?

Safety Features: Are the over-current, over-voltage, and short-circuit protections functioning correctly?

Cable Functionality: Does the spiral cable transmit power effectively and retract properly?

7. Cleaning, Appearance Check, and Packaging: The Final Touches

Once a charger passes all the functional tests, it's time for the finishing touches. The device is meticulously cleaned to remove any fingerprints or dust. A final visual inspection ensures that the appearance is flawless, with no scratches or blemishes.

Finally, the 20W fast car charger with its spiral cable is carefully packed into its retail color box, complete with user manuals and any other accessories. This ensures that the product not only performs perfectly but also arrives in pristine condition.

Ready to experience the convenience and speed of a 20W fast car charger with a spiral cable? Contact me now .The below video shows a very detailed process for the production :

How a 20W fast car charger work

How a 20W fast car charger work

How to made 20W fast car charger with a spiral cable ?

How to made 20W fast car charger with a spiral cable ?

Quality Control for LiRui USBC Charger workshop

Quality Control for LiRui USBC Charger workshop

Quality control for Lirui USB cable workshop

Quality control for Lirui USB cable workshop